With the long overhangs, the boats motion was very soothing. We gently rose up the face of the wave and then slumped down the back of the wave. Only one wave boarded us, and that was while trying to point into the wind. It hit us directly on the beam, and the crest of the wave came in between the top and bottom lifelines. We instantly had 1 foot of water in the cockpit, which then drained almost instantly through the 4 large scuppers. This should be a reminder of why you want to keep the scuppers clean; if they had been clogged with dog hair, we would have had a pool in the cockpit for quite some time.

This is also why we only open the top dropboard in the companionway. If it were open, then all of this water would have also gone into the cabin.

The winds were blowing 30 knots apparent and we were running along doing 6 knots with just the storm sails up, so approximately 36 knots true. We checked the wind charts on Passage Weather (passageweather.com) and saw that we were listed having 20 knots, so it was blowing much harder than they were calling for. Meanwhile, Cape Hatteras was showing winds of 35 knots.

There was a storm off of Cape Hatteras that would continue to blow for the next three days. Being how I was trying to make Maddie like ocean sailing, I figured jumping into that would be unwise for the safety of our boat and our cruising future.

What I would have done, was work my way off the shore, and then heave to for the next few days, waiting for the storm on the cape to pass. Then I would have made my way around the Diamond Shoal after the present insanity had passed.

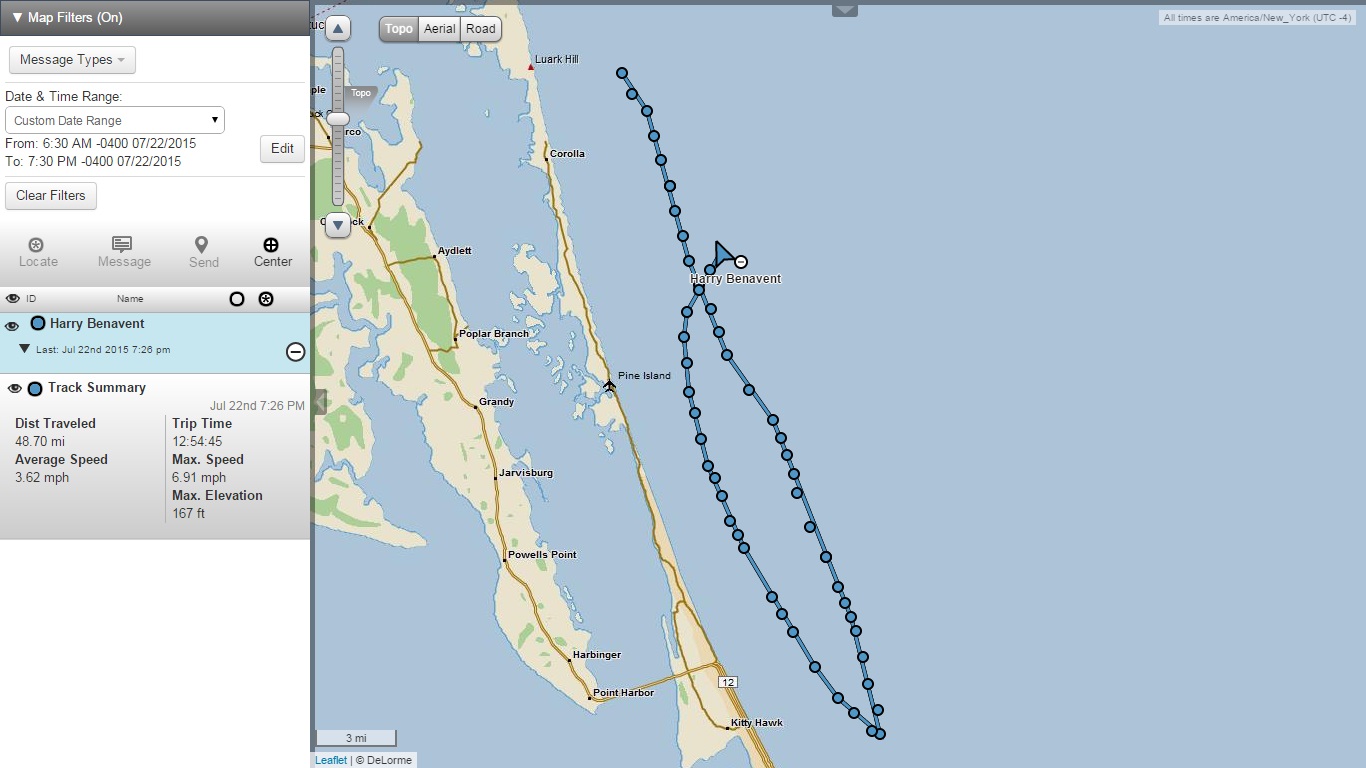

I got the feeling that Maddie has had enough around 7 AM when she said she wanted to turn around and start heading North.

This was fine, but the winds and seas did not agree with our plan. We trimmed the sails to keep the boat steady but to be less efficient so that our speed would slow from 6 knots to 2 to 3 knots. We also let the painter on Tooth out much farther, the idea being the extra line in the water would cause more drag and help slow us down a bit. With 200 feet of painter out, we didn't see Tooth for a long time.

When we would look back, we would see the painter going straight into the wall of water behind us. We thought that Tooth had sunk, turning into a sea anchor. After a few hours, we finally saw tooth pop over a wave crest, almost like if he was trying to wave hello to us. Tooth was still floating!

At 1PM, the winds had died down to 12 knots. I was still flying the storm sails as I was convinced the winds would return. The seas died down to only a few feet and the winds dropped to only 10 knots. With this change, I went forward to hoist the main, with 2 reefs in it.

I must have looked like an abused animal in a horrible experiment. When the beatings stopped, I stood waiting for them to resume at any moment.

After around 10 minutes with this set up, I saw that the winds did not return. I shook out 1 of the reefs and waited another 10 minutes. Then raised the jib and waited another 10 minutes, then shook out the last reef finally sailing under full sail.

By this time, the winds were very light, blowing 8 to 12 knots as we made our way North into the swells from the storm that had passed over us. As the afternoon drew on, we made our way offshore for the night. The skies were clear and the forecast was for a calm night, so we hove to with the staysail and the main with 2 reefs.

I wanted to spend my birthday this year out in the ocean, and I did get to, but what a wild christening it was to the world of ocean sailing. It turns out that Maddie enjoyed the day since she never felt in danger. We were prepared with the right sails up for the coming winds and the boat ran before the storm comfortably. While it wasn't the day of ocean sailing I envisioned, it was awesome to test out all of the theory I had learned over the years.

The most important thing about ocean sailing is preparedness! If we had more sail up, we would have had a horrible time trying to get the storm sails rigged in a blow. By setting everything up when it was still calm, crew safety was guaranteed. If I had not been doing watches, we would have awaken closer to shore or even on shore! Then we would have had a horrible ride taking the waves on the stern quarter while trying to broad reach the storm to work off the leeward shore.

We couldn't sheet the trisail in enough to point upwind, so we would have been forced to use 2 reefs in the main. For the future, we are planning on adding a 3rd and 4th reef to our mainsail, along with reefs in our jib and staysail.