Stainless steel is a wonderful metal that "stains less" than regular steel. Regular steel will begin to rust when left exposed to air and moisture as the iron in it will form a layer of iron oxide. Stainless steel will not rust as quickly because it contains more chromium which forms a protective layer of chromium oxide on the surface. This protective layer shields the rest of the metal from the corroding, giving stainless steel its wonderful qualities.

While stainless steel won't rust the way regular steel will, it does corrode in a distinct fashion: Crevice Corrosion. Crevice corrosion occurs in areas where the chromium oxide layer has broken down, usually in areas that are deprived of oxygen or very moist or exposed to acidic vapors.

Chainplates usually live in closed up and tight areas of the boat where crevice corrosion can begin. This in combination with the immense stress placed on these metal pieces can lead to fractures and breaks in the chainplate.

While crevice corrosion does show warning signs, they are often overlooked as they are miniscule. The most common sign of crevice corrosion are horizontal fracture lines running perpendicular to the loads placed on the chainplate.

One recommended method to find these fracture lines is to remove the metal fitting, wash it with acid and scrub it completely clean; then inspect the metal piece under a bright light with strong magnification. As you can imagine, this method is highly impractical!

The method I use is to look closely at the metal fitting with a strong light source aiming at it. I do not use magnification or any other fancy gadget. As a dentist I have a lot of experience with finding microscopic cracks in teeth. I am able to see these fractures with my naked eye, and you can too if you take the time to look closely at the metal in front of you. Imagine that there is a crack in the metal and you need to prove that it's not there. When you see it, you know it's there; alternatively, when you can't find it, you were proven wrong. With this frame of mind, you will be more focused on finding the smallest of flaws in the item you are inspecting.

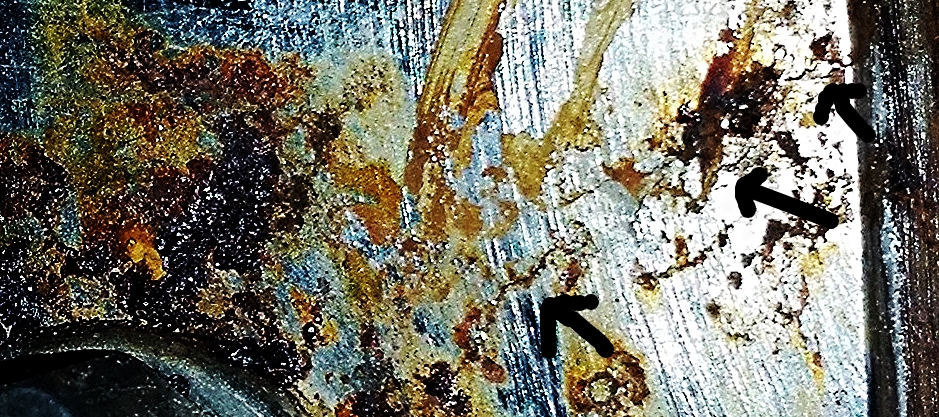

Do you see the fracture line?

This is the same image but heavily zoomed and contrasted to accentuate the fracture line, along with some helpful arrows point to the crack. Can you see the crack line on the original image?

These cracks are tiny and tend to occur horizontally across the surface due to the combination of stress and corrosion. Eventually, they will lead to catastrophic failure!

Keep a close eye on your stainless steel fittings for these tiny cracks. The moment you see them, it is time for immediate replacement of that part.