Synthetic lifelines allow you to replace your questionable steel lifelines with dyneema that will provide you with a very lightweight lifeline that is immune to corrosion and easy to install yourself. The only specialty component that you need to make the conversion is a gate latch that can be spliced onto a synthetic lifeline. These latches cost around $70 each, and are readily attainable at most chandleries.

Synthetic lifelines are tensioned with lashings that attach to the pulpits. If you cut your lifelines a bit short, you don't need to worry since this will only require you to use a longer lashing.

The biggest issue with synthetic lifelines is chafe. You need to be mindful of sheets rubbing on them, as well as chafe from the stanchions that they pass through. The other issue is the spliced portion of the lifeline will not fit through the stanchion.

Chafe from the sheets can be managed by adjusting the sheet leads, but the chafe of the stanchion can not be avoided. The lifeline will rub on the stanchion because the lifeline passes through the stanchion. The trick is to polish the passage through the stanchion so that the chafe point is reduced.

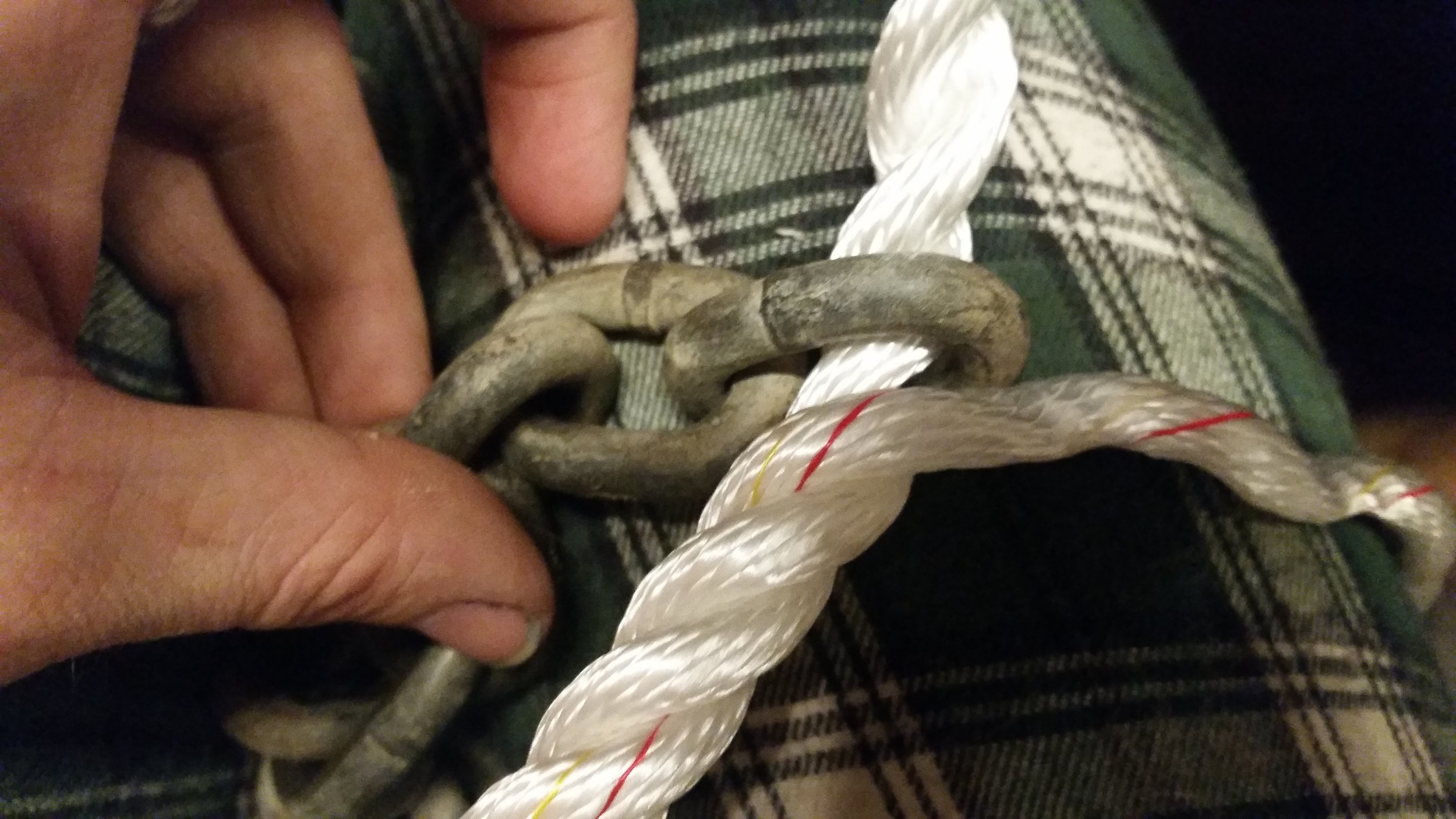

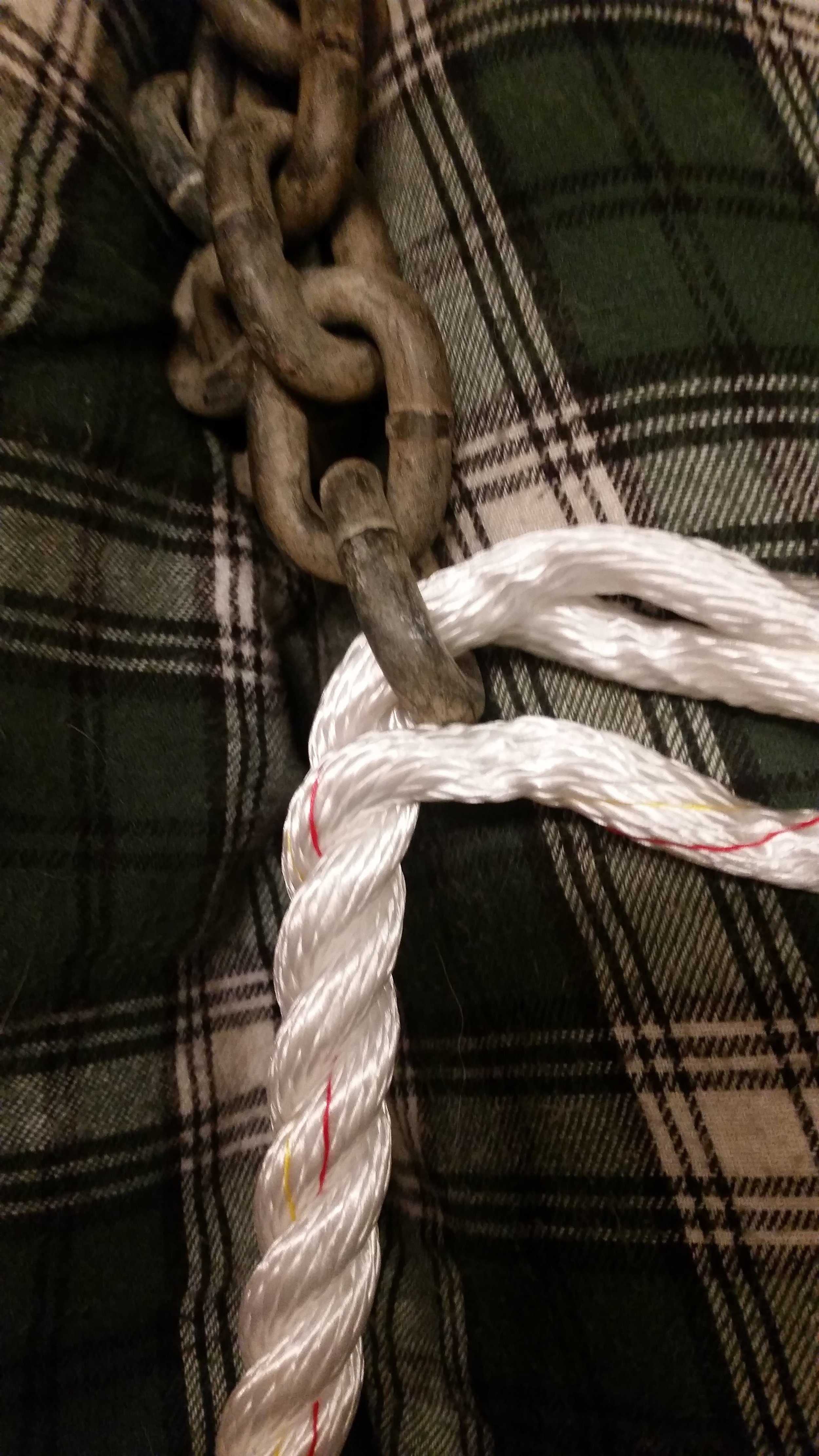

As far as the splicing goes, there is a trick to work the splice around the stanchion. The splice is simply passed over the outside of the stanchion so that the bulk is bypassed. Be sure to leave enough room to scoot the spliced area over to inspect for chafe.