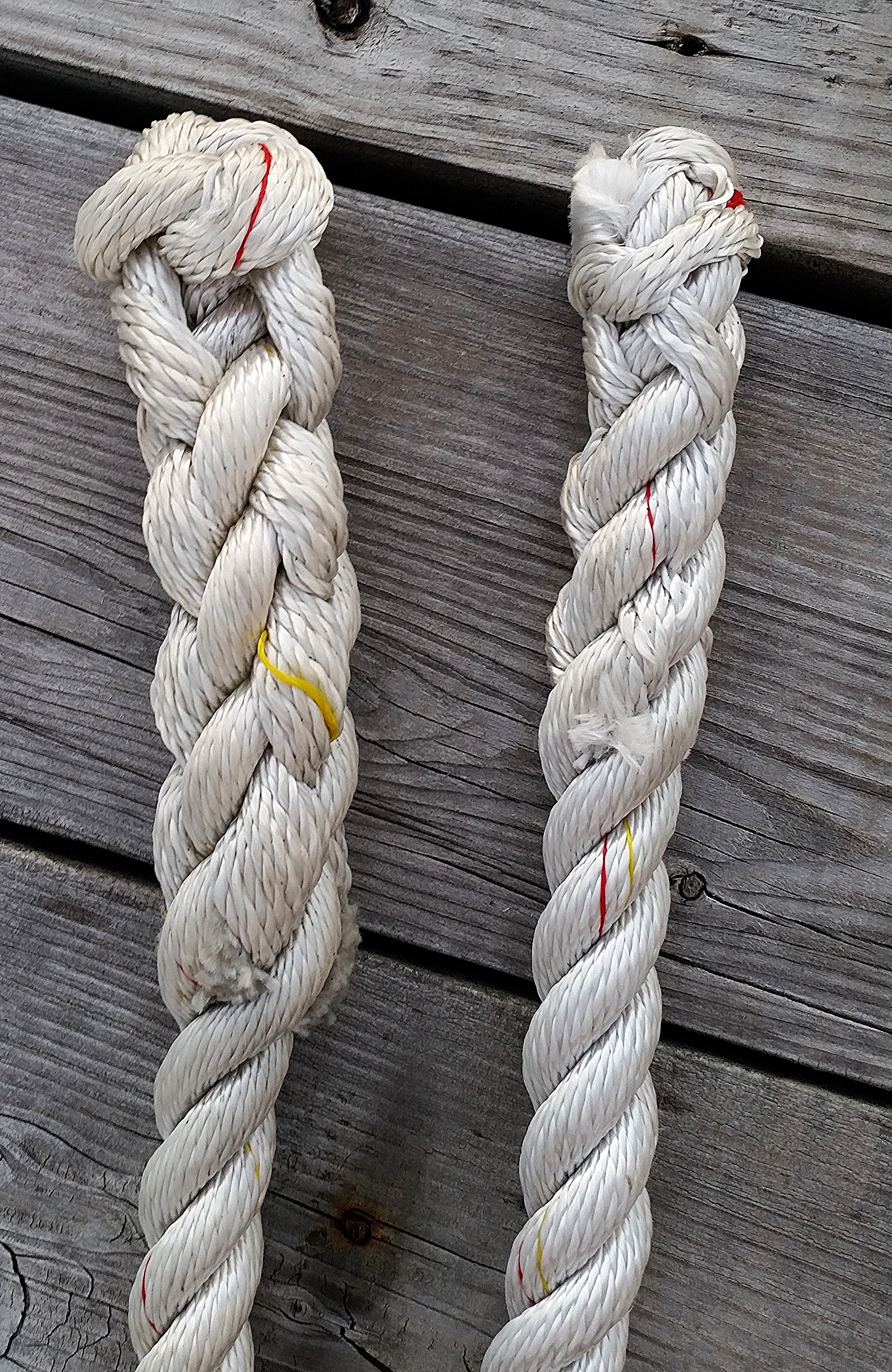

I began a new project! I'm building rope fenders that will replace by plastic inflatable ones and also serve the purpose of a fender board. If you would like me to make rope fenders for you as well, let me know what size you want and I can give you an estimate.

I currently have two 10"x26" Taylor Made fenders, and they are not enough for when we tie up to a pier or raft up with friends. My options are add more fenders to my vessel (and figure out where to store them) or make myself rope fenders to meet my needs.

The fenders need to accomplish the following:

Be light enough for Maddie to deploy them

Be soft to protect from impacts

Cover the opening in the gate so that Morty can't fall out

Be long enough to serve as fender boards

I was going to make 2 very large and long fenders, but quickly decided that their weight would make them difficult to manage which would result in us never using them. I then switched ideas to making 4 large and long fenders that are easier to store and deploy.

The fenders are also going to double as a way to close the bottom of the gate while we are under sail. Morty loves to sit on the leeward side, right next to the gate with his head hanging out over the toe rail (this is why we keep him tied to the jacklines to make recovery easier if he were to slip off the side). This is the only place on the boat where the netting to keep him on board is missing, and it is his favorite place to sit.

By being long enough to serve as both fenders and fender boards, we will be protected in any docking and rafting situation while only needing to carry four rope fenders on board.